DeepMould: Your Trusted Die Casting Supplier

Introduction

Welcome to DeepMould, the leading provider of high-quality die casting services. As a trusted metal fabricator, we offer a wide range of solutions for businesses in need of precision parts and components. With our advanced technology, skilled workforce, and commitment to excellence, we ensure that your die casting needs are met with utmost satisfaction.

Why Choose DeepMould for Your Die Casting Needs?

When it comes to selecting a die casting supplier, you want a partner who can meet your unique requirements and deliver exceptional results. DeepMould offers several benefits that set us apart from other metal fabricators:

1. Extensive Experience and Expertise

With years of industry experience, DeepMould has become a reputable name in the field of die casting. Our team of experts possesses the knowledge and expertise required to handle complex projects, ensuring the highest level of precision and quality. We have successfully served clients across various industries, including automotive, aerospace, electronics, and more.

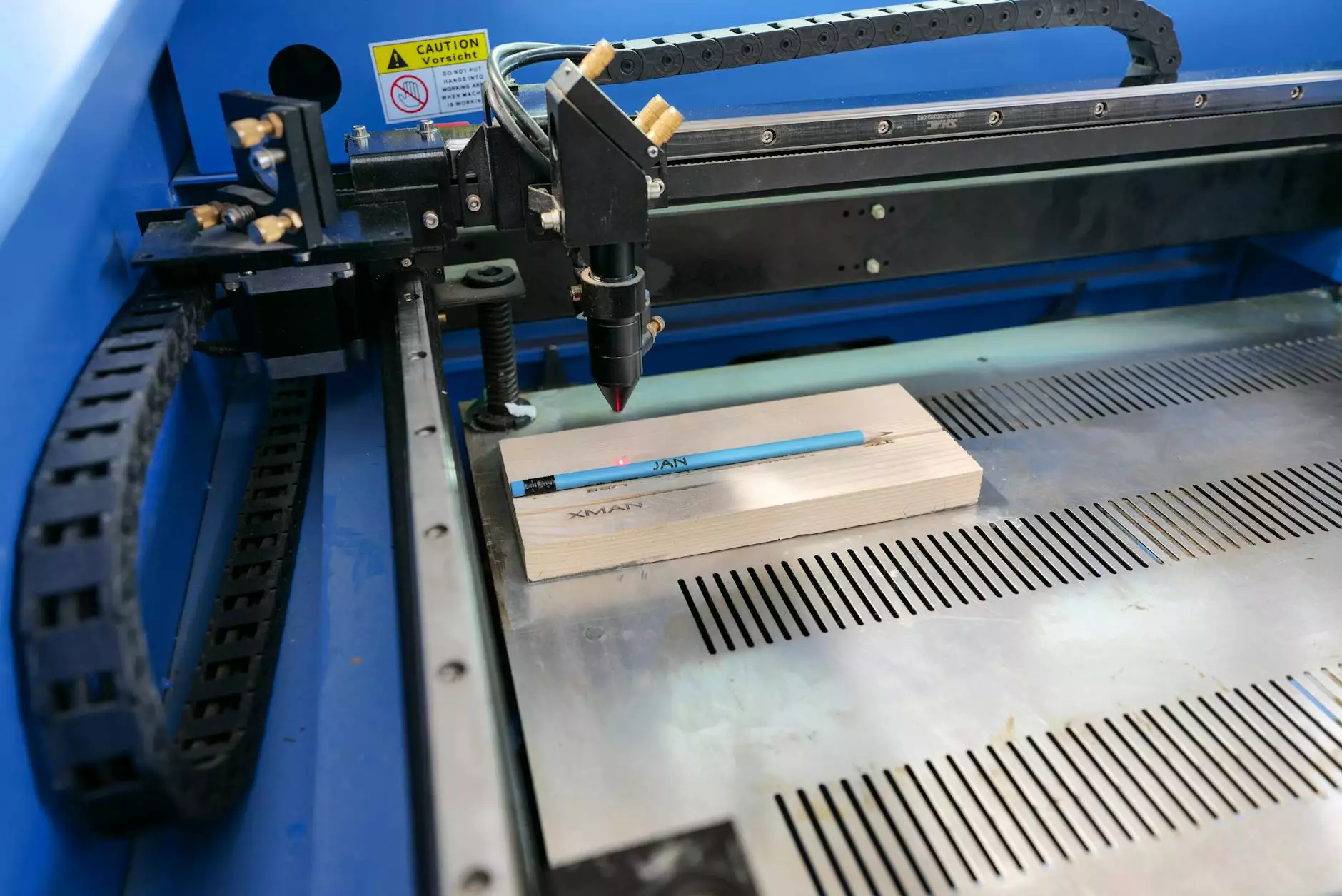

2. State-of-the-Art Facilities

At DeepMould, we understand the importance of investing in cutting-edge technology. Our state-of-the-art facilities are equipped with advanced casting machines, CNC machining centers, and quality inspection equipment to ensure seamless production processes. This allows us to deliver top-notch quality products consistently.

3. Customization Options

We believe in providing customized solutions to meet our clients' specific needs. Whether you require complex geometries, unique designs, or specific material properties, our skilled engineers and technicians work closely with you to turn your ideas into reality. We leverage advanced software and prototyping techniques to develop tailor-made die casting solutions that exceed your expectations.

4. Quality Assurance

Quality is our top priority at DeepMould. We adhere to stringent quality control measures throughout the production process to ensure that every product leaving our facility meets the highest industry standards. Our dedicated quality control team conducts thorough inspections and tests to guarantee the dimensional accuracy, mechanical properties, and surface finish of each component.

5. Competitive Pricing

DeepMould believes in providing exceptional value for your investment. We offer competitive pricing without compromising on quality, making us a cost-effective choice for your die casting needs. By streamlining our manufacturing processes and optimizing material utilization, we minimize costs while maintaining the highest level of craftsmanship.

The Die Casting Process

Die casting is a highly efficient manufacturing process that offers numerous advantages for producing complex metal components. Here's an overview of the die casting process:

1. Tooling Design and Fabrication

The die casting process begins with tooling design and fabrication. Our expert engineers analyze your component's specifications and develop precise molds or dies. These dies are then fabricated using advanced techniques and cutting-edge machinery to ensure accuracy and durability.

2. Melting and Injection

Next, the chosen metal alloy is melted in our state-of-the-art furnaces under precise temperature control. Once the metal reaches the desired molten state, it is injected into the die cavity using high-pressure techniques. Our advanced injection systems guarantee the consistent and uniform filling of the molds, minimizing defects and improving product integrity.

3. Cooling and Solidification

After injection, the molten metal is left to cool and solidify within the die cavity. Our expert technicians monitor the cooling process to maintain optimal cooling rates, ensuring the formation of a solid, high-quality component. The time required for cooling depends on the complexity and size of the component.

4. Ejection and Finishing

Once the component is solidified and cooled, it is ejected from the die cavity using ejection pins or mechanisms. The ejected part may undergo additional finishing processes, such as trimming, shot blasting, deburring, or surface treatment, to achieve the desired appearance and functional properties. Our skilled workforce ensures that each component meets your specifications and quality requirements.

Applications of Die Casting

Die casting finds applications in various industries due to its versatility and ability to produce intricate and complex components. Here are some common applications of die casting:

- Automotive: Die casting is widely used in the automotive industry for manufacturing engine components, transmission housing, braking systems, and more.

- Aerospace: The aerospace sector relies on die casting for producing lightweight, high-strength components used in aircraft, satellites, and space exploration equipment.

- Electronics: Die casting is prevalent in the electronics industry for manufacturing computer parts, connectors, enclosures, and other electronic devices.

- Industrial Machinery: From manufacturing tools to heavy machinery components, die casting plays a crucial role in various industrial applications.

- Consumer Goods: Die casting is used in the production of numerous consumer goods, such as appliances, lighting fixtures, furniture hardware, and decorative items.

Conclusion

Choosing the right die casting supplier is crucial for your business's success. DeepMould, with its extensive experience, state-of-the-art facilities, and commitment to quality, emerges as a reliable partner for all your die casting needs. Partnering with us ensures precision, customization, and cost-effectiveness, allowing you to stay ahead in the competitive market. Contact DeepMould today to discuss your project requirements and experience the difference of working with a leading metal fabricator!