Injection Molding Plastic Products - The Future of Manufacturing

Introduction

Welcome to DeepMould, your one-stop solution for all your metal fabrication needs. We specialize in injection molding plastic products, providing high-quality manufacturing services across various industries. In this article, we will explore the advantages of injection molding and its role in shaping the future of manufacturing.

The Power of Injection Molding

Injection molding revolutionized the manufacturing industry by offering a cost-effective and efficient method for producing high-quality plastic products. The process involves injecting molten plastic material into a custom-designed mold, which then solidifies to form the desired shape. This technique allows for intricate designs, precise dimensions, and consistent product quality.

Advantages of Injection Molding

There are several key advantages to using injection molding for your plastic product manufacturing needs:

1. Cost-Effective Production

Injection molding enables mass production of plastic products at a significantly lower cost compared to traditional manufacturing methods. The high production output, combined with minimal material waste, translates into cost savings for your business.

2. Design Flexibility

With injection molding, you have endless design possibilities. The flexibility of the process allows for the creation of complex geometries, thin walls, and intricate details. Whether you need small components or large parts, injection molding can fulfill your design requirements.

3. Fast Turnaround Times

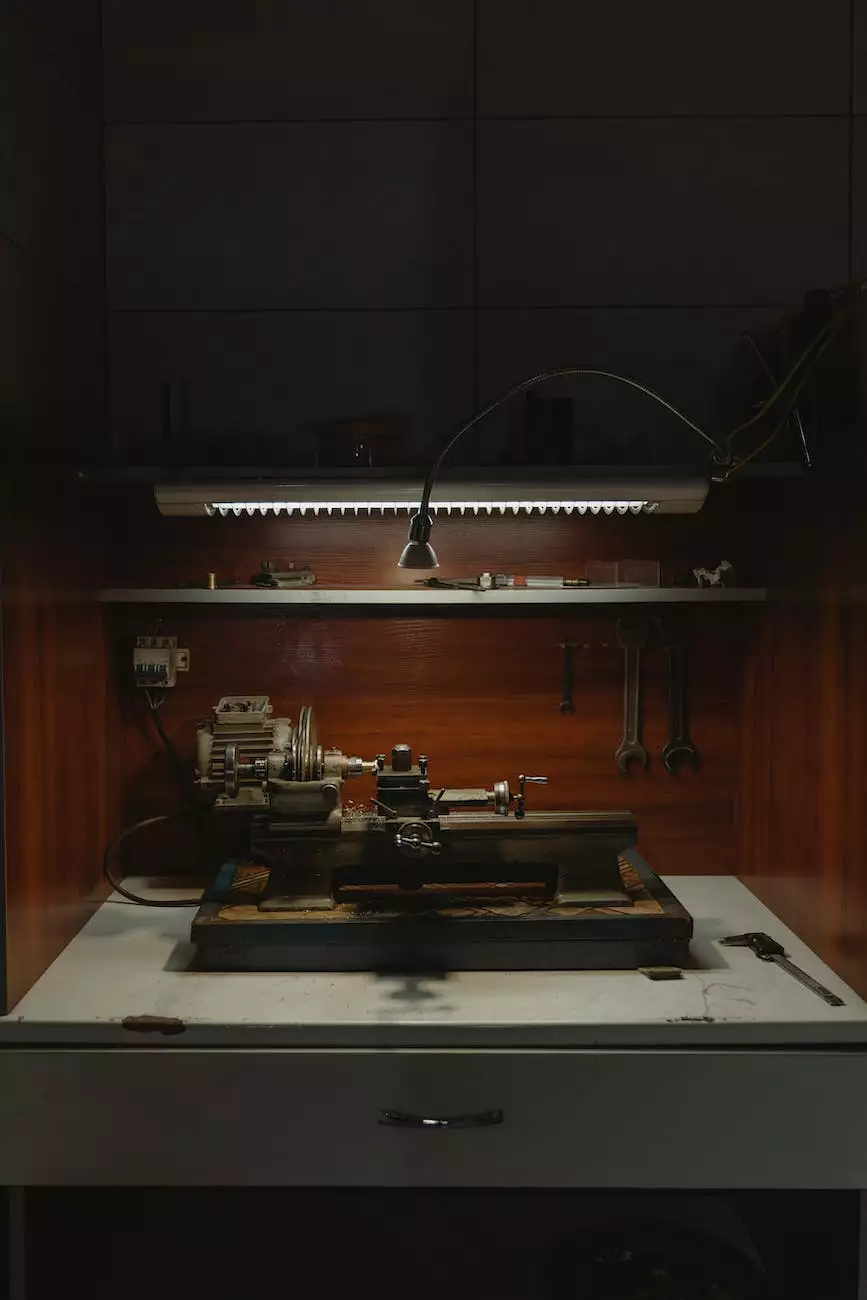

Time is crucial in today's competitive business landscape. Injection molding offers rapid production cycles, ensuring quick turnaround times for your plastic products. Our advanced machinery and streamlined processes allow us to deliver orders on time without compromising quality.

4. Product Consistency

Consistency is paramount in product manufacturing. With injection molding, each product undergoes the same production process, ensuring uniformity and quality control. This level of consistency is essential in industries such as automotive, healthcare, and consumer electronics.

5. Material Compatibility

Injection molding supports a wide range of plastic materials, including thermoplastic polymers, elastomers, and engineering resins. This versatility allows you to choose the right material that meets your product requirements in terms of strength, durability, and chemical resistance.

Applications of Injection Molding Plastic Products

The use of injection molding extends across various industries, enabling the creation of innovative and functional plastic products:

1. Automotive Industry

Injection molding plays a vital role in manufacturing automotive components such as exterior body panels, interior parts, and intricate engine components. The ability to produce lightweight and durable plastic parts makes injection molding a preferred choice in the automotive sector.

2. Medical and Healthcare

Precision and cleanliness are critical in the medical field. Injection molding facilitates the production of medical devices, equipment, and disposable items with tight tolerances and sterile requirements. From syringes to surgical instruments, injection molding ensures the highest standards of quality and safety.

3. Consumer Electronics

The consumer electronics industry heavily relies on injection molding for the production of casings, connectors, buttons, and other components. The aesthetic appeal, durability, and precision achieved through injection molding enhance the functionality and overall user experience of electronic devices.

4. Packaging

Injection molding provides a cost-effective solution for manufacturing plastic packaging products, including bottles, containers, caps, and closures. The ability to produce consistent and reliable packaging ensures product safety and extends shelf life.

Partner with DeepMould for Your Injection Molding Needs

At DeepMould, we are committed to delivering exceptional metal fabrication services, including injection molding plastic products. Our skilled team of professionals, state-of-the-art machinery, and quality assurance protocols ensure the highest standards of excellence for every project we undertake.

Our extensive experience in the industry, coupled with a customer-centric approach, makes us the preferred choice for businesses across various sectors. Whether you need prototypes, small-scale production, or mass manufacturing, we have the capabilities to meet your requirements with precision and reliability.

Visit our website, deepmould.net, to learn more about our injection molding services and explore our portfolio. Contact us today to discuss your project and experience the future of manufacturing with DeepMould.