Business Success with Laser Marking Equipment

Are you involved in the metal fabrication industry and looking for innovative ways to enhance your business? Look no further than DP Laser! With our state-of-the-art laser marking equipment, we offer solutions that can help take your business to new heights. In this article, we will explore the benefits and features of laser marking equipment and how it can contribute to the success of your metal fabrication business.

Why Laser Marking Equipment Matters in Metal Fabrication

Metal fabrication is a competitive industry, and staying ahead of the curve is crucial for business success. Laser marking equipment plays a pivotal role in enhancing efficiency, precision, and productivity in your everyday operations. By incorporating laser technology into your metal fabrication processes, you can reap numerous benefits.

Laser marking offers unparalleled precision and accuracy, allowing you to create intricate designs and markings on various metal surfaces. Whether you need to engrave serial numbers, barcodes, logos, or other unique identifiers, laser marking ensures a permanent and high-quality result. The clarity and durability of laser markings make them ideal for industries that require traceability, such as automotive, aerospace, and medical devices.

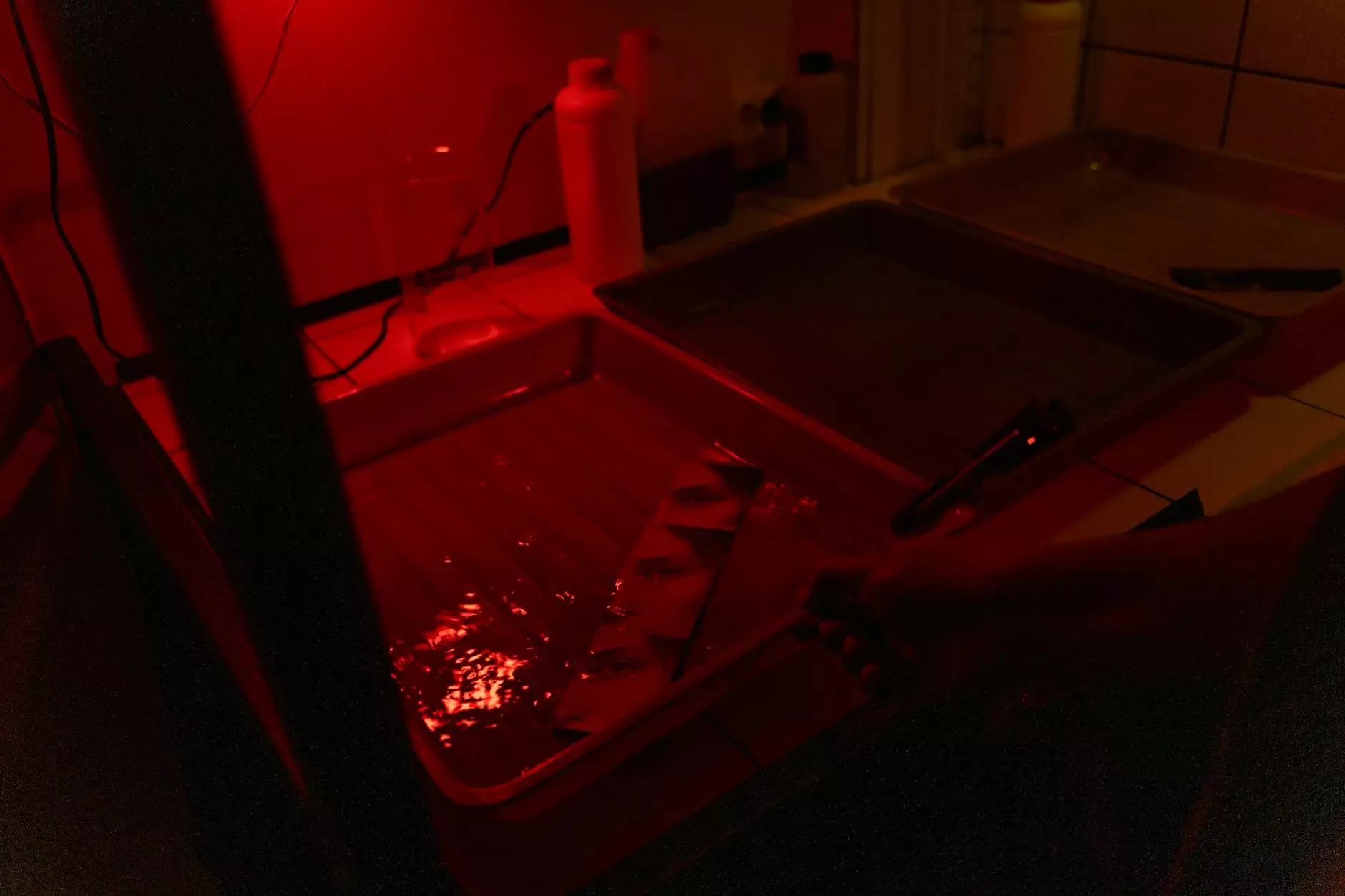

Overview of DP Laser's Laser Marking Equipment

At DP Laser, we specialize in providing top-of-the-line laser marking equipment tailored to the metal fabrication industry. Our cutting-edge technology is designed to meet the highest standards of performance, reliability, and precision.

When it comes to laser marking equipment, we offer a wide range of options to suit your specific needs. From fiber laser marking systems to CO2 laser marking machines, our selection ensures that you can find the perfect solution for your metal fabrication requirements.

Our laser marking equipment stands out due to its exceptional speed and accuracy. With advanced features like galvanometer scanning heads and auto-focus capabilities, you can achieve fast marking speeds without compromising on precision. This allows for high-volume production without sacrificing quality or efficiency.

The Competitive Edge of DP Laser's Laser Marking Equipment

Investing in DP Laser's laser marking equipment gives your business a significant competitive edge. Here's how our equipment stands out from the crowd:

1. Unparalleled Durability:

DP Laser's laser marking systems are built to last. Our equipment is constructed with high-quality materials and undergoes rigorous testing to ensure durability, even in demanding production environments. With our laser marking machines, you can enjoy reliable performance for years to come.

2. Versatility and Flexibility:

Our laser marking equipment is highly versatile and can handle a wide range of materials, including stainless steel, aluminum, copper, and more. Whether you are working with flat sheets, tubes, or 3D surfaces, our machines deliver consistent results across different types of metal fabrication projects.

3. Ease of Use:

We understand the importance of seamless integration into your existing workflow. That's why DP Laser's laser marking equipment is designed with user-friendliness in mind. Intuitive interfaces and software make the operation of our machines straightforward, allowing your team to adapt quickly and efficiently.

4. Cost-Efficiency:

Investing in laser marking equipment from DP Laser offers long-term cost savings for your business. Our machines require minimal maintenance and have low operating costs. Additionally, the consistent accuracy and speed of laser marking help avoid costly errors and rework, ultimately maximizing productivity.

Unlocking Business Potential with DP Laser

By integrating DP Laser's laser marking equipment into your metal fabrication processes, you unlock significant potential for growth and success. Here are some key benefits you can expect:

Enhanced Product Quality:

Laser marking ensures an impeccable finish on your products, enhancing their overall quality and value. Consistent and professional markings provide a positive impression to your customers and build brand reputation.

Increased Efficiency and Productivity:

Ditch traditional marking methods and embrace laser technology for improved efficiency and productivity. Laser marking enables faster processing times, shorter setup durations, and minimal downtime, allowing you to ramp up production while meeting client deadlines.

Advanced Customization and Design Flexibility:

With laser marking, you have the freedom to create intricate designs and personalized markings to meet the unique requirements of your clients. This level of customization sets your business apart from the competition and appeals to niche markets.

Enhanced Traceability and Compliance:

For industries that require strict traceability and compliance standards, laser marking is the ideal solution. The permanent and highly legible markings ensure proper identification, tracking, and compliance with regulations.

Cost Savings and Return on Investment:

While the initial investment may seem substantial, laser marking equipment offers long-term cost savings. By minimizing errors, reducing scrap, and streamlining production processes, you will experience a significant return on investment in the long run.

Conclusion

In today's competitive metal fabrication industry, leveraging cutting-edge technology is vital for sustainable success. DP Laser's laser marking equipment provides the essential tools you need to elevate your business to new heights. With our state-of-the-art machines, you can achieve unparalleled precision, efficiency, and productivity, ultimately driving your profitability forward. Don't wait! Explore the possibilities and invest in DP Laser's laser marking equipment today to position your business at the forefront of the industry.