OEM Lathe Machining Parts Manufacturers: Driving Innovation in Precision Engineering

In today's highly competitive manufacturing landscape, companies are continually seeking innovative solutions to enhance their productivity and efficiency. Among the myriad technologies reshaping the industry, OEM lathe machining parts manufacturers stand out as pivotal players driving precision and excellence.

Understanding OEM Lathe Machining

OEM, or Original Equipment Manufacturer, refers to companies that produce parts and equipment that may be marketed by another manufacturer. Lathe machining is a manufacturing process used to shape and design materials, primarily metals, into precise components. In this context, lathe machining involves removing material from a rotating workpiece using cutting tools to achieve specific shapes, sizes, and finishes.

The Importance of Precision in Manufacturing

Precision in manufacturing is paramount, particularly in industries such as aerospace, automotive, and medical devices. The role of OEM lathe machining parts manufacturers is crucial in providing components that meet stringent tolerances and specifications. High-quality lathe machining parts ensure the integrity of the final assemblies and systems, thus contributing to the overall reliability and performance of products.

Key Advantages of Choosing OEM Lathe Machining Parts

When organizations opt for OEM solutions in lathe machining, they unlock several key advantages:

- High Quality and Consistency: OEM manufacturers often adhere to strict quality control measures, resulting in consistent production of high-quality parts.

- Innovative Technologies: OEM manufacturers invest in the latest technology and techniques, ensuring that their processed parts utilize the most efficient machining methods.

- Customization: Many OEMs offer bespoke machining services tailored to meet the specific demands of their customers.

- Expertise and Knowledge: Established OEM manufacturers possess extensive industry experience and can provide valuable insights and solutions for unique challenges.

- Cost-Effectiveness: By streamlining processes and employing advanced technologies, OEMs can often provide machining services at competitive prices.

The Evolution of OEM Lathe Machining Parts Manufacturers

The landscape of manufacturing has transformed significantly over the years. Here’s how OEM lathe machining parts manufacturers have evolved:

Adoption of Advanced Technologies

Modern manufacturers are increasingly embracing technologies like computer numerical control (CNC), which has revolutionized lathe machining. CNC allows for automated precision cutting, enabling manufacturers to produce intricate parts with exceptional accuracy and repeatability.

Sustainability in Manufacturing Practices

In response to global sustainability challenges, many OEM lathe machining parts manufacturers have implemented eco-friendly practices. These include:

- Waste Reduction: Efficient use of materials and recycling practices minimize waste.

- Energy Efficiency: Adoption of energy-efficient machinery helps reduce the carbon footprint of manufacturing processes.

- Sustainable Materials: Increased use of recyclable and sustainable materials in production.

Applications of OEM Lathe Machining Parts

The versatility of lathe machining makes it applicable in numerous sectors. Key applications include:

Aerospace Industry

In aerospace, precision is non-negotiable. OEM lathe machining parts are used in components such as turbine blades, brackets, and landing gear parts, where safety and reliability are critical.

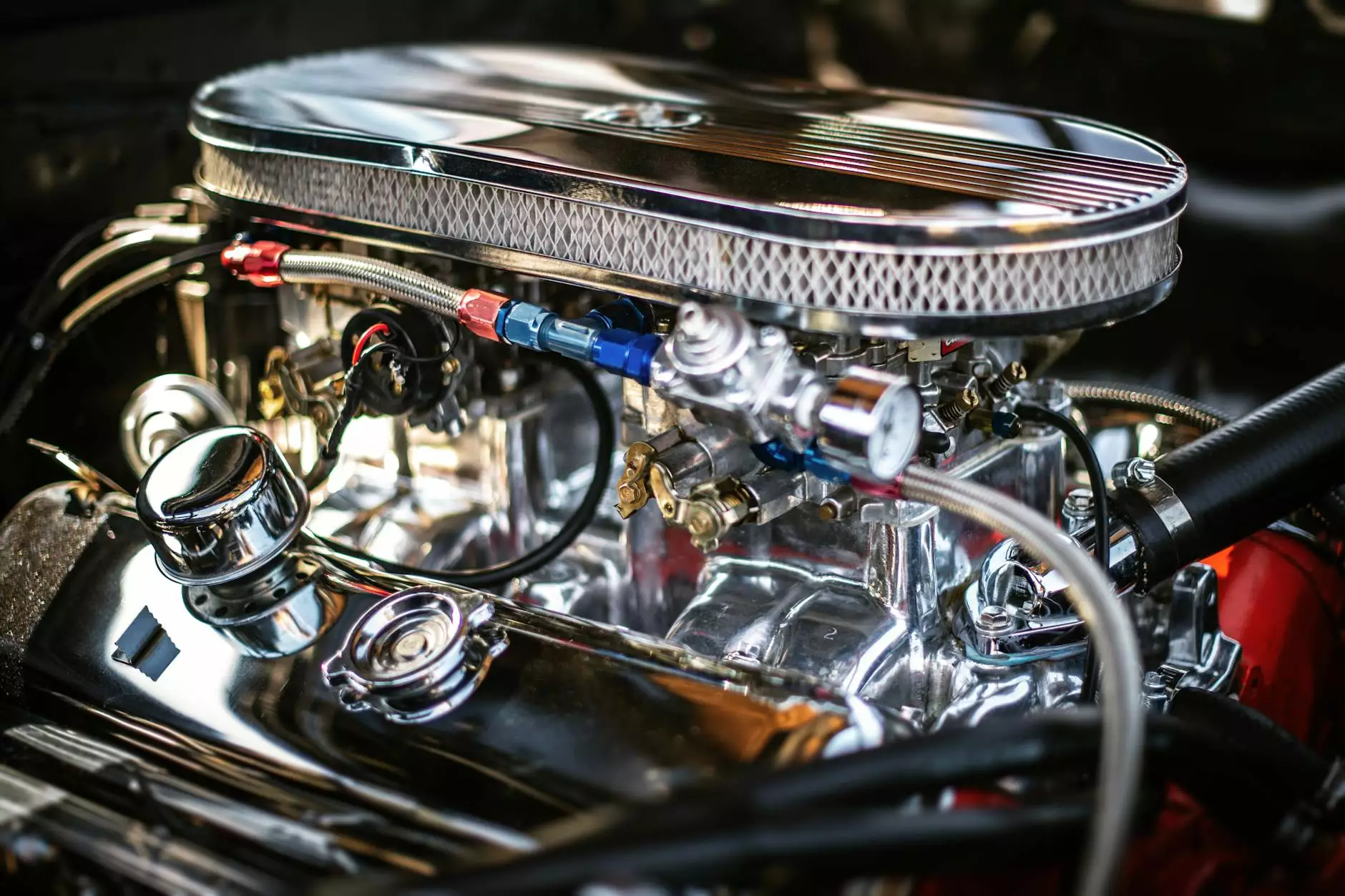

Automotive Industry

Manufacturers in the automotive sector rely heavily on lathe machining for various components, including engine parts, transmission components, and chassis parts. The ability to produce complex geometries at scale makes lathe machining indispensable.

Medical Devices

In the medical field, the accuracy of machining is crucial for patient safety. Components such as surgical instruments and implantable devices often rely on OEM lathe machining to meet stringent regulatory standards.

Choosing the Right OEM Lathe Machining Parts Manufacturer

Selecting the right OEM lathe machining parts manufacturer can significantly impact your business outcomes. Here are several factors to consider:

- Industry Experience: Choose a manufacturer with a proven track record in your particular industry.

- Quality Certifications: Ensure they possess necessary certifications such as ISO 9001 to guarantee quality management.

- Technological Capabilities: Evaluate their machinery and technology levels to ensure they meet your production needs.

- Customer Reviews: Research customer testimonials and case studies to gauge their reliability and service quality.

- Financial Stability: A financially stable manufacturer is more likely to invest in the necessary technology and resources for quality production.

The Future of OEM Lathe Machining Parts Manufacturing

The future looks bright for OEM lathe machining parts manufacturers. As technology continues to advance, we can expect:

Increased Automation

Manufacturers will likely invest more in automation technologies to improve efficiency and reduce labor costs while maintaining or enhancing quality levels.

Integration of Artificial Intelligence

AI will play a substantial role in predicting maintenance needs, optimizing production processes, and improving design parameters, leading to smarter manufacturing environments.

Customization and Flexibility

As businesses seek personalized solutions, OEM manufacturers that provide customizable lathe machining options will be well-positioned to thrive in the evolving market landscape.

Conclusion

OEM lathe machining parts manufacturers are essential partners in driving the future of precision engineering. Their commitment to quality, innovation, and sustainability positions them at the forefront of manufacturing excellence. As industries continue to evolve, these manufacturers will play a critical role in meeting the demands of modern technology and consumer expectations.

For businesses looking to leverage high-quality machining solutions, aligning with reputable OEM lathe machining parts manufacturers like those represented at deepmould.net can lead to enhanced productivity and success in the competitive marketplace.