The Ultimate Guide to Choosing the Right ROC CNC Router for Your Business

The manufacturing industry is evolving rapidly, with advancements in technology leading to greater efficiency and precision. One such advancement is the use of ROC CNC routers, which have emerged as indispensable tools for a variety of businesses, from woodworking to metal fabrication. In this comprehensive guide, we will explore everything you need to know about ROC CNC routers, their features, benefits, and applications, helping you make an informed decision for your business.

What is a ROC CNC Router?

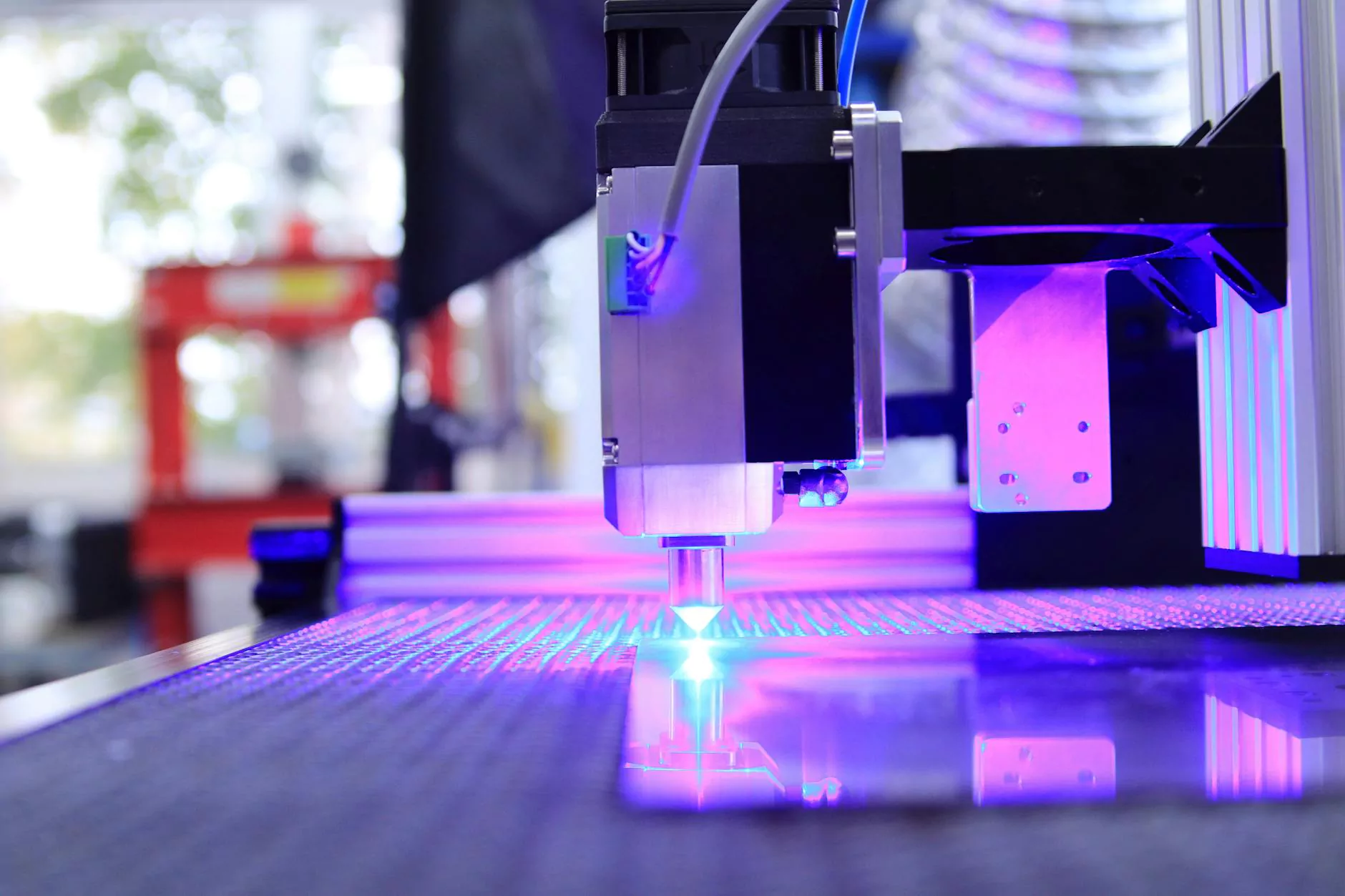

A ROC CNC router is a computer-controlled cutting machine that can carve, cut, and engrave various materials with high precision. Unlike manual routers, CNC stands for Computer Numerical Control, which means that these routers operate based on a pre-programmed set of commands. This automation allows for intricate designs and exceptionally consistent results, making them a popular choice in numerous industries.

Key Features of ROC CNC Routers

- High Precision:ROC CNC routers are designed to achieve remarkable accuracy, often within a tolerance of 0.01mm, ensuring that even the most complex designs can be executed flawlessly.

- Versatile Material Compatibility: These routers can work with various materials, including wood, plastics, metal, and composites, making them suitable for diverse applications.

- User-Friendly Software: Most ROC CNC routers come with intuitive software that simplifies the design process, allowing users to create, import, and modify designs with ease.

- Durable Construction: Built with robust materials and components, ROC CNC routers are engineered for longevity, capable of withstanding the rigors of daily use in busy production environments.

- Customizable Options: Depending on your specific needs, you can find various configurations and add-ons for ROC CNC routers, including different spindle options, sizes, and tool changers.

Benefits of Using a ROC CNC Router

Incorporating a ROC CNC router into your business operations can yield a myriad of benefits:

- Increased Productivity: By automating cutting and engraving processes, ROC CNC routers enable businesses to complete projects in significantly less time compared to traditional methods.

- Consistent Quality: The precision of ROC CNC routers reduces the likelihood of human error, resulting in uniform products that meet high-quality standards.

- Reduced Labor Costs: Automation allows for fewer workers on the floor, reducing labor costs while maintaining output levels.

- Design Freedom: The capability to create complex and intricate designs opens up new avenues for product development, enhancing innovation and creativity.

- Ease of Use: With user-friendly software and controls, even those with minimal technical expertise can quickly learn to operate a ROC CNC router, minimizing training time.

Applications of ROC CNC Routers

The versatility of ROC CNC routers means they can be used in numerous industries. Here are some common applications:

1. Woodworking

From intricate furniture designs to cabinetry, ROC CNC routers are ideal for woodworking professionals looking to create stunning pieces with intricate details.

2. Sign Making

Create custom signs, logos, and lettering with the precision and quality that ROC CNC routers offer, allowing for personal branding and marketing needs to be met effectively.

3. Prototyping

Engineers and designers can rapidly produce prototypes of their products, helping to streamline the design process and bring innovative ideas to life faster than ever.

4. Metal Fabrication

With appropriate tooling, ROC CNC routers can also carve and shape metals, making them a powerful tool in fabrication workshops.

5. Arts and Crafts

Artists can use ROC CNC routers to create complex designs and sculptures that would be impossible to carve by hand, elevating their artistic creations.

Choosing the Right ROC CNC Router

Selecting the right CNC router for your business involves consideration of several factors:

- Business Needs: Assess your specific applications—do you need a router primarily for wood, metal, or mixed materials?

- Machine Size: Consider the workspace available and the size of the projects you typically handle. Larger machines can accommodate more extensive workpieces.

- Budget: Determine your budget for both initial investment and ongoing operation costs.

- Support and Training: Ensure the manufacturer offers robust customer support and training resources to help you get the most from your machine.

- Reviews and Reputation: Research user reviews and the reputation of the brand. Look for testimonials on performance and reliability.

Why Choose ROC Technology

When considering a ROC CNC router, ROC Technology provides a myriad of advantages:

- Expertise: ROC Technology specializes in CNC machines and has a rich history of innovation and quality.

- Customer Service: Their commitment to customer service ensures you will receive support whenever you need it.

- Customization: ROC Technology offers tailored solutions to fit the specific needs of your business.

- Training and Resources: They provide comprehensive training and resources, ensuring that you maximize your router's potential.

Maintenance and Care for Your ROC CNC Router

To ensure your ROC CNC router remains in excellent condition and operates efficiently, regular maintenance is crucial. Here are some essential maintenance tips:

- Clean Regularly: Dust and debris can affect the precision of your machine. Regularly clean the work area and the machine itself.

- Inspect Components: Regularly check the router's components, such as bearings, belts, and bits, to ensure they are in good condition.

- Software Updates: Stay up-to-date with the latest software updates to ensure optimal performance and access to new features.

- Lubricate Moving Parts: Periodically lubricate the moving parts to reduce friction and prevent wear.

- Seek Professional Help: If you encounter issues, don’t hesitate to seek help from ROC Technology’s support team.

The Future of ROC CNC Routers

The future of manufacturing looks bright with advancements continuously being made in CNC technology. ROC CNC routers are at the forefront of this evolution, incorporating the latest innovations to improve efficiency, reduce costs, and enhance the quality of the final product. As industries grow and new applications are discovered, the versatility of ROC CNC routers will only increase, making them a valuable investment for any business.

Conclusion

In conclusion, if you are considering upgrading your business's manufacturing capabilities, investing in a ROC CNC router could be a game changer. With their precision, versatility, and efficiency, these machines can significantly enhance your productivity and product quality. Whether you are engaged in woodworking, metal fabrication, or any other industry requiring high-quality cutting and engraving, the ROC CNC router from ROC Technology stands out as a premier choice. Explore the range of options available at roc-tech.com to find the perfect CNC router that meets your business needs.