The Ultimate Guide to Prototype Injection Molding Services

Introduction

Welcome to the ultimate guide to Prototype Injection Molding Services provided by deepmould.net! Whether you are a startup or an established company, deepmould.net is your go-to destination for all your metal fabrication needs. As leaders in the industry, they specialize in Prototype Injection Molding Services, offering high-quality solutions that can help bring your products to life.

Why Choose Prototype Injection Molding Services?

Prototype Injection Molding Services play a crucial role in the product development process. It allows businesses to create functional prototypes and test them rigorously before moving forward to mass production. With deepmould.net's extensive experience in the field, they understand the intricate requirements of various industries, making them the perfect partner for your next project.

The Benefits of Prototype Injection Molding Services

There are numerous benefits to utilizing Prototype Injection Molding Services for your business:

1. Accelerated Product Development

By opting for deepmould.net's Prototype Injection Molding Services, you can significantly reduce the time and cost associated with product development. Traditional manufacturing methods can be time-consuming and expensive, while prototype injection molding allows for rapid iteration and refinement of designs. With quick turnaround times, you can speed up your product development cycle and stay ahead of the competition.

2. Cost-Effective Solutions

deepmould.net understands the importance of cost-effectiveness in today's competitive market. Prototype Injection Molding Services offer a cost-effective solution by minimizing material waste and streamlining the manufacturing process. By choosing deepmould.net, you can expect premium quality services at competitive prices, saving both time and money in the long run.

3. Design Flexibility

When it comes to product development, design flexibility is crucial. deepmould.net's Prototype Injection Molding Services provide the flexibility to experiment with various designs, materials, and finishes. This flexibility ensures that you can achieve the desired functionality and aesthetics of your product, allowing for true innovation and customization.

4. High-Quality Products

deepmould.net prides itself on delivering high-quality products to its clients. Their team of skilled metal fabricators ensures that each prototype is meticulously crafted to meet and exceed industry standards. With their state-of-the-art facilities and dedication to quality, you can trust that your prototypes will reflect the excellence and precision your business demands.

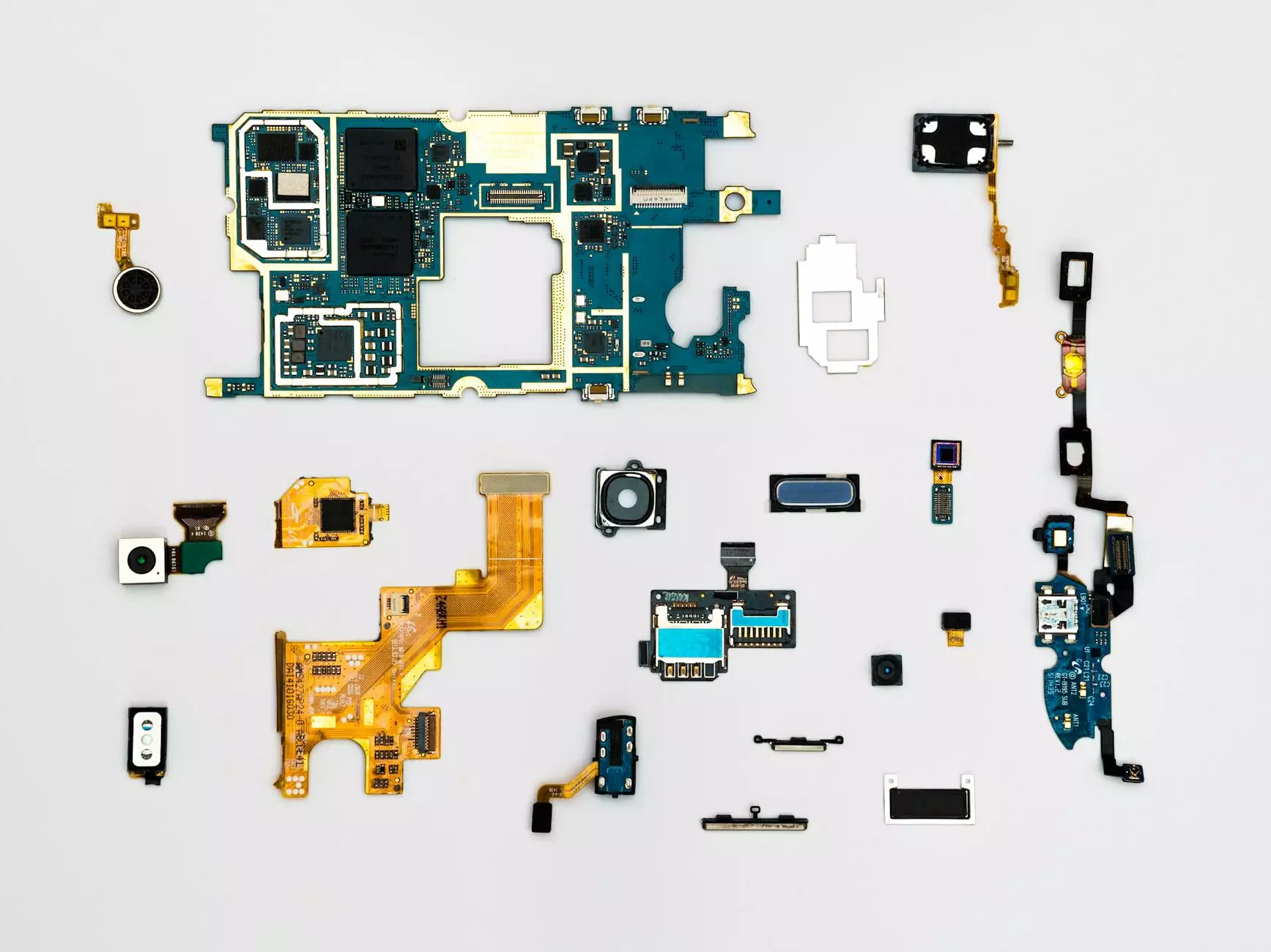

The Prototype Injection Molding Process

deepmould.net follows a well-defined process to ensure the success of your prototype injection molding project:

1. Design Collaboration

At deepmould.net, the process begins with a thorough understanding of your design requirements. Their team of experts collaborates closely with you to optimize the design for manufacturability, ensuring that your prototypes can go seamlessly into mass production when the time comes.

2. Material Selection

Choosing the right materials is crucial for the success of any injection molding project. deepmould.net offers an array of materials to suit your specific needs, be it durability, flexibility, or heat resistance. Their knowledgeable team guides you in selecting the ideal material that meets your project's requirements, ensuring optimal performance.

3. Tooling and Prototyping

deepmould.net leverages cutting-edge technology and advanced equipment to create precise and accurate molds for your prototypes. Their metal fabricators meticulously craft the molds with attention to detail, leaving no room for errors. Once the molds are ready, the injection molding process begins, transforming your design into a tangible reality.

4. Quality Assurance

Quality is of utmost importance at deepmould.net. Each prototype undergoes rigorous testing and inspection to ensure it meets the highest standards before moving forward. Their quality assurance processes include dimensional checks, material testing, and functional analysis, guaranteeing that your prototypes perform flawlessly.

5. Iteration and Feedback

deepmould.net understands the importance of iteration and continuous improvement. Through feedback and collaboration with their team, you can refine and enhance your prototype until it seamlessly aligns with your vision and objectives. This iterative process provides the opportunity to perfect your product before mass production, saving you time and resources.

Conclusion

When it comes to Prototype Injection Molding Services, deepmould.net is the industry leader you can trust. Their expertise, commitment to quality, and customer-centric approach set them apart from the competition. By choosing deepmould.net, you are investing in a reliable partner that understands your business needs and can deliver exceptional results.

Experience the benefits of high-quality Prototype Injection Molding Services today. Contact deepmould.net to discuss your project requirements and witness your ideas come to life with precision and excellence.